Challenge:

Many businesses face labor shortages, repetitive strain injuries, and inconsistent output in manual packing and palletizing processes. This cell demonstrates how a flexible automation solution can overcome these challenges.

Solution:

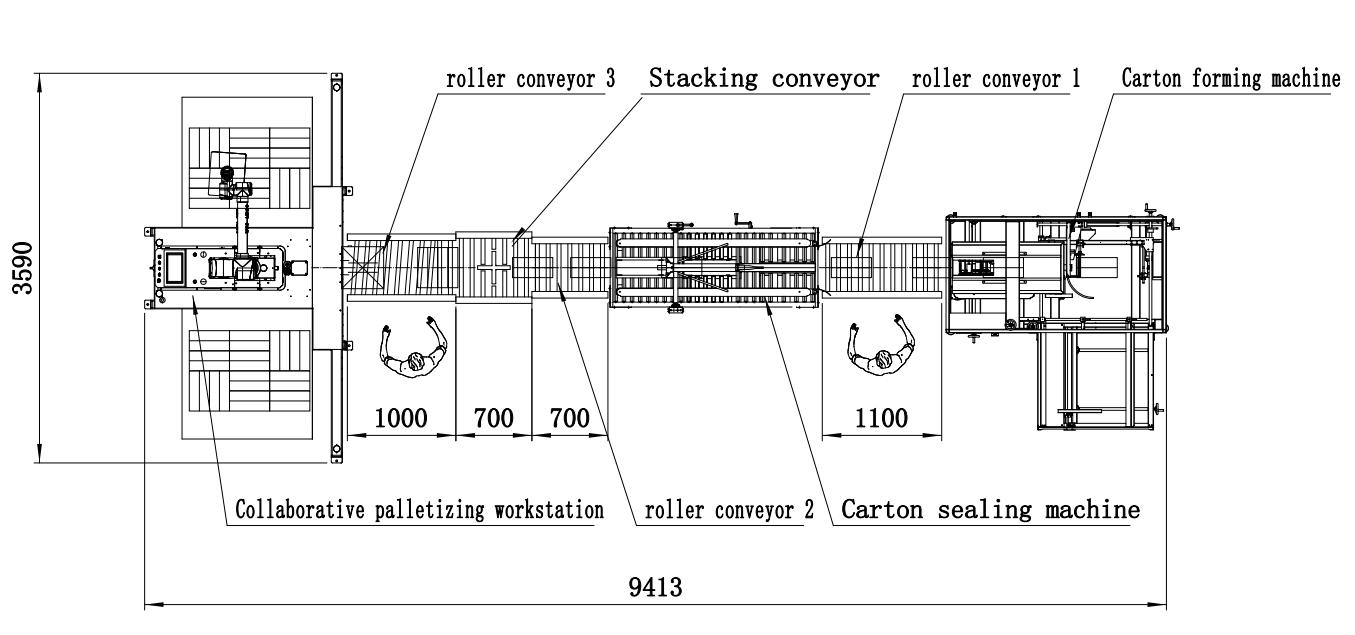

We implemented a core collaborative robot (cobot) palletizing workcell, seamlessly integrated with upstream packaging automation. The system includes a cobot, a conveyor system, and two pallet stations. It can be easily expanded with an automatic case erector, a carton sealer, and an inkjet printer for a complete end-to-end solution.

System Workflow:

How It Works – A Seamless Automated Flow:

Automatic Case Erection: An operator loads blank corrugated cases into the automatic case erector. The machine automatically picks, forms, and tapes the bottom of each case, then conveys it forward.

Manual Loading Station: The case stops on a roller conveyor where an operator manually places the products inside. Once loaded, a simple step on a foot pedal signals the conveyor to move the case to the next stage.

Automatic Sealing: The case enters the carton sealer, which folds the top flaps and securely applies tape. The sealed box is then conveyed to the next stage.

Print & Apply: A 90-degree rotating conveyor orientates the case to present the short side for a clear, precise date code application by the inkjet printer.

Efficient Cobot Palletizing: The finished box is conveyed into the cobot's picking area. The versatile cobot gripper can pick one or two boxes per cycle (as programmed) and places them onto the pallet in the required pattern. For unique case designs like open-top boxes, the gripper can be modified.

Value Delivered:

Value Delivered:

Reduced Labor Costs & Ergonomic Risk: Automates the heavy and repetitive task of palletizing, freeing staff for higher-value roles and eliminating strain injuries.

Increased Efficiency & Output: The system operates at a consistent, high pace. The ability to double-handle two boxes simultaneously significantly boosts throughput.

Unmatched Flexibility: The collaborative nature of the system allows for safe operation alongside employees. Quick changeover between different box types and pallet patterns is simple.

Space-Saving Footprint: The compact, integrated workcell maximizes floor space utilization without the need for extensive safety fencing.

Rapid ROI: By combining labor savings, higher throughput, and reduced product damage, this automated solution delivers a compelling return on investment.

Ready to transform your packaging line? Contact Autron to discuss a tailored solution for your business