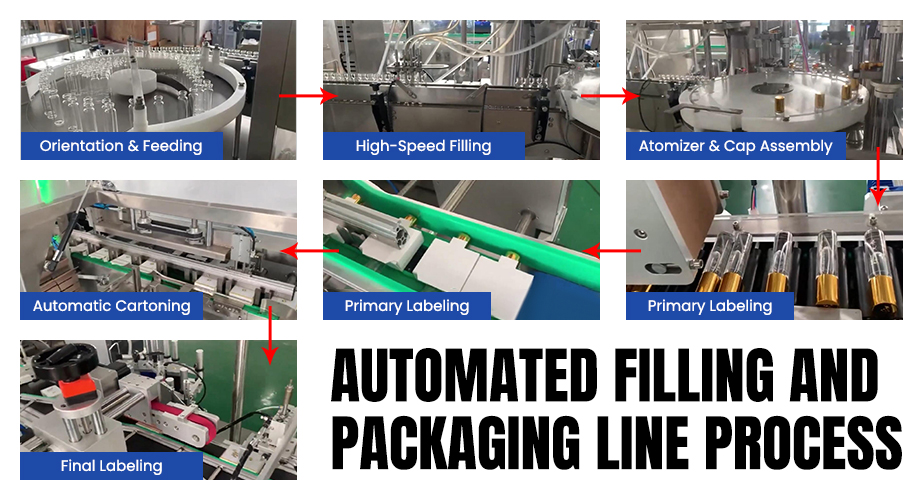

This case details a fully automated, high-efficiency packaging line designed and implemented by Autron Tech for a prestigious perfume brand. The system seamlessly integrates filling, capping, labeling, and cartoning processes into one continuous flow, significantly boosting output while ensuring precision and elegance.

The Integrated Process:

1. Orientation & Feeding: Perfume bottles are singulated and precisely oriented on a large rotary indexing table, ensuring a consistent and orderly flow into the production line.

2. High-Speed Filling: Four servo-driven pumps operate simultaneously to fill the perfume into the bottles with exceptional accuracy, eliminating volume variation.

3. Atomizer & Cap Assembly: The nozzle is automatically placed, and the cap is then screwed on tightly through a precision capping station.

4. Primary Labeling: A high-resolution label is automatically applied to the bottle body with perfect placement and zero wrinkles.

5. Cardboard Insert Placement: A dedicated paper tray (or blister card) is automatically sleeved over the bottle to secure it firmly for retail presentation.

6. Automatic Cartoning: The packaged bottle is then gently pushed into a pre-formed carton. The machine automatically folds and locks both the bottom and top flaps, ensuring a secure closure.

7. Final Labeling: An external label or price tag is automatically applied to the finished carton, completing the ready-to-ship package.

Value Delivered:

This Autron system replaces multiple manual stations, dramatically reducing labor costs and human error. It guarantees a flawless, salon-quality finish for every unit, enhancing brand prestige and ensuring a rapid return on investment.