It is a type of vertical form-fill-seal (VFFS) system designed to create a pouch with seals on all four sides. The key advantages of this packaging style are its exceptional product visibility, a modern and premium appearance that stands out on retail shelves, and excellent barrier properties for extended product freshness. It is a versatile and reliable solution for high-speed production lines seeking a polished, consistent package finish.

This machine is highly efficient and automated, making it ideal for packaging a wide range of products, including snacks, powders, granules, and hardware components.

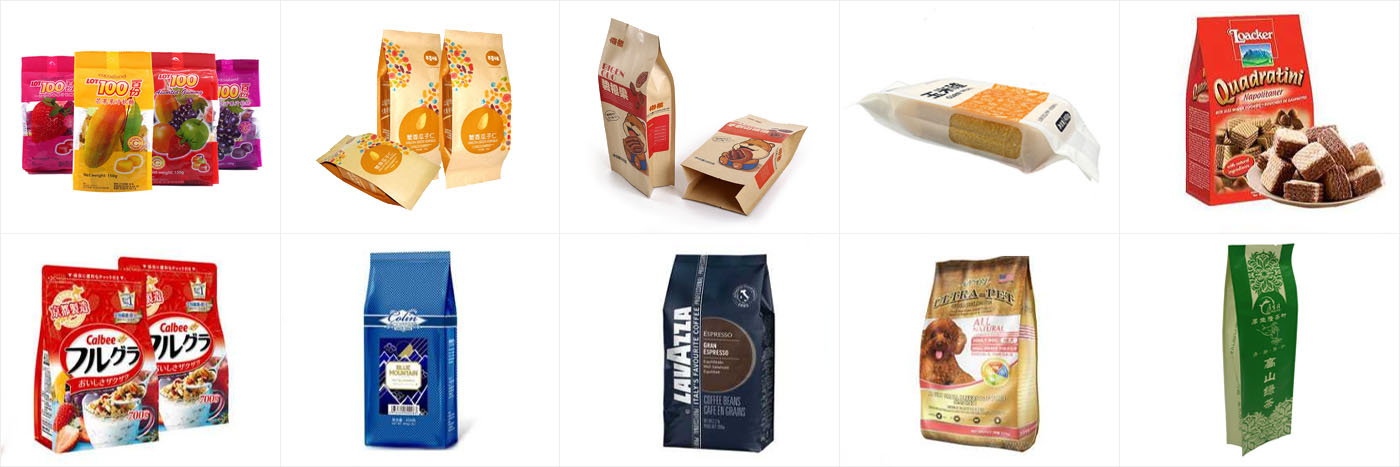

Applications:

Suitable for automatic packaging of various kinds of leavened food.candies, peanuts, seeds and such materials in grain or piece as well as powder like milk powder, washing powder, starch, etc.

Specification:

Model | BAP-420 | BAP-520 | BAP-680 |

Film width | 150-Max. 420 mm | 250-Max. 520 mm | 260-Max. 680 mm |

Bag length | 80-280 mm | 80-350 mm | 80-420 mm |

Bag width | 80-132 mm | 80-150 mm | 80-220 mm |

Bag height | 20-66 mm | 35-90 mm | 40-110 mm |

Longitudinal sealing width | 5-10 mm | ||

Film roll diameter | Max. 320 mm | ||

Packaging speed | 10-40 Bag/min (According to user requirements) | 10-30 Bag/min | |

Range of measurement | 150-1500ml | 150-2000ml | 150-2500ml |

Film thickness | 0.04-0.08 mm | ||

Power | 220V 50Hz 2.8Kw | 220V 50/60Hz 3Kw | 220V 50Hz 3.8Kw |

Machine size | (L)1390×(W)1155×(H)1800 mm | (L)1492×(W)1255×(H)2184 mm | (L)1590×(W)1500×(H)2408 mm |

Machine weight | About 600Kg | About 700Kg | About 800Kg |