An industrial Case Filling Station, often using high-speed "spider hand" (delta robot) automation, is designed for high precision and speed in packaging lines. These robotic arms swiftly pick products from a conveyor and accurately place them into awaiting cases or cartons. This system significantly boosts efficiency, reduces labor costs, and minimizes product damage compared to manual packing.

Our Features:

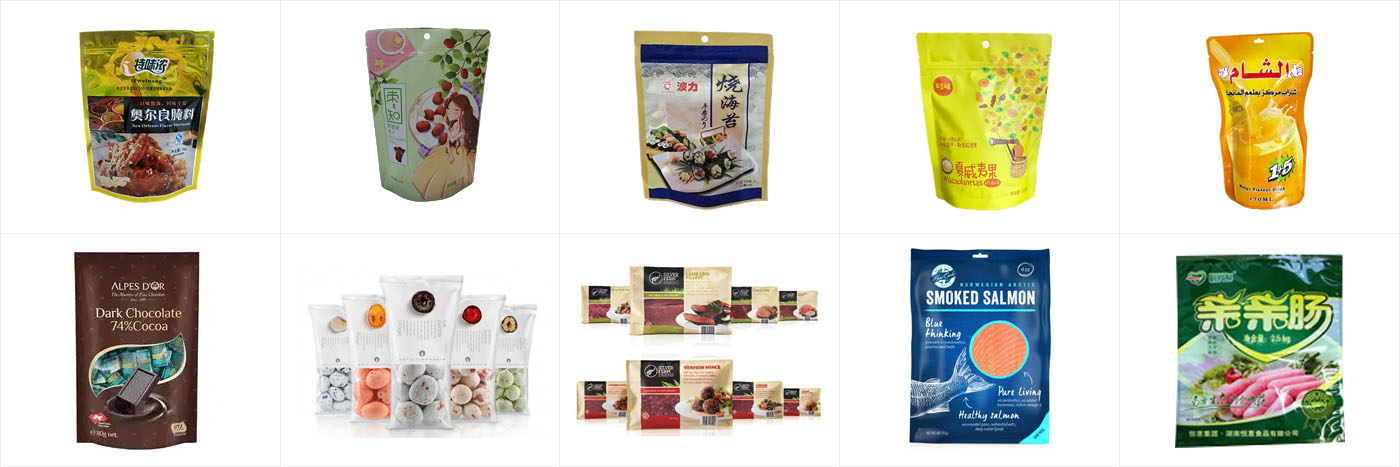

1. The use of high-speed flexible parallel robots for grabbing movements ensures the stable operation of products during high-speed grabbing and transportation. It is widely used in automatic identification, sorting and boxing of soft bag products such as fast-selling foods and meat products.

2. The whole machine has precise and compact structure design, few spare parts, easy maintenance and repair, and low maintenance cost.

3. It occupies a small space and can be set up to work in a small space, which improves the efficiency of site use. The control method adopts handheld teaching pendant + standard control button + signal switch, which is simple to operate and convenient for maintenance.

4. It is optional to integrate an Vision Guidance System (VGS), for better guiding the robot to pick up the products precisely.

Specifications:

Applicable product specifications | 10g-2000g |

Packing speed | 40-100次/min |

Applicable carton size | Slotted carton: L 100-480×W 150-380×H 150-400 mm |

Applicable Products | Soft bagged food, daily necessities, hardware accessories, etc. |

Advantage | Flexible conversion, high speed and efficiency |

Main body material | Main body carbon steel paint |

Power | 5Kw |

Rated loading | ≤3Kg Including gripper |

Machine size | (L)2350×(W)1730×(H)2360 mm |

Cooperate with robots | WSC-1000D/WSC-1200D |

Machine weight | About 800Kg |

Product Application

Best-selling food and meat products, such as soft-packaged items