This system use Estun robot to pick up the cases from the conveyor, stack the case onto the pallets according to client’s program. Client can set the stacking layout from the HMI.

System consists of:

1. Roller conveyor

2. Safety fence

3. Palletizing Robot

4. Pallets conveyor (Optional)

5. Control system

6. Pallets feeding system (Optional)

Working Steps:

1. Wroker place the empty pallets into the storage silo of the pallet feeder.

2. Pallet feeder feed the empty pallet onto the pallet conveyor

3. Pallet conveyor convey the empty pallet to the correct position beside the robot.

4. The robot craps the carton boxes onto the pallets according to preset requirement.

5. The control system open the safety gate after the palletizing is finished, and convey out the loaded pallets.

6. Meanwhile, the pallet feeder drops one empty pallet onto the conveyer, hense starts the next recycle.

7. Once the loaded pallet arrived the preset position, there will have alarm, so worker (or AGV) can take away the pallet.

Specifications:

4-axis palletizing robot ER120-2400 | |

Maximum Load | 120 kg |

Arm Span | 2400 mm |

Repeat Positioning Accuracy | ±0.2 |

Control Cabinet Input Power | 3ph 4wire AC380V 50HZ |

I/O Module | 24 inputs and 24 outputs reserved |

Interconnection cable | standard 8 meters |

Co mmunication interface with peripheral equipment | accept ModBus TCP, TCP/IP and other bus co mmunications |

CPU | 800MHZ |

Memory | 128M |

Touch color display | 7 inches |

Memory | 128M |

Co mmunication interface | Ethernet |

5. Pallet Feeder | |

Lifing Method | by pneumatic cylinder |

Operating System | Fully automatic distribution system (PLC+ touch screen +inverter) |

Pallet sizes | standard series, can be customized according to client's products |

Pallet Storaging Capacity | 10-12 pcs |

Distribution efficiency | 25 second/piece |

Lifting Weight | 350kg |

Lifting height | 200 mm |

Lifting cylinder | Φ100*200*2 |

Clamping cylinder | Φ40*175*2 |

Conveyor height | 500±50 mm |

Conveyor width | 1250 mm |

Conveyor roller | t2.0*Φ76 mm, roller wheelbase 127 mm |

Conveying speed | 10-18m/min |

Air Consumption | 0.4-0.6MPa |

Power supply | 3-phase 5-wire AC220V50Hz |

Total Power | 2.3KW |

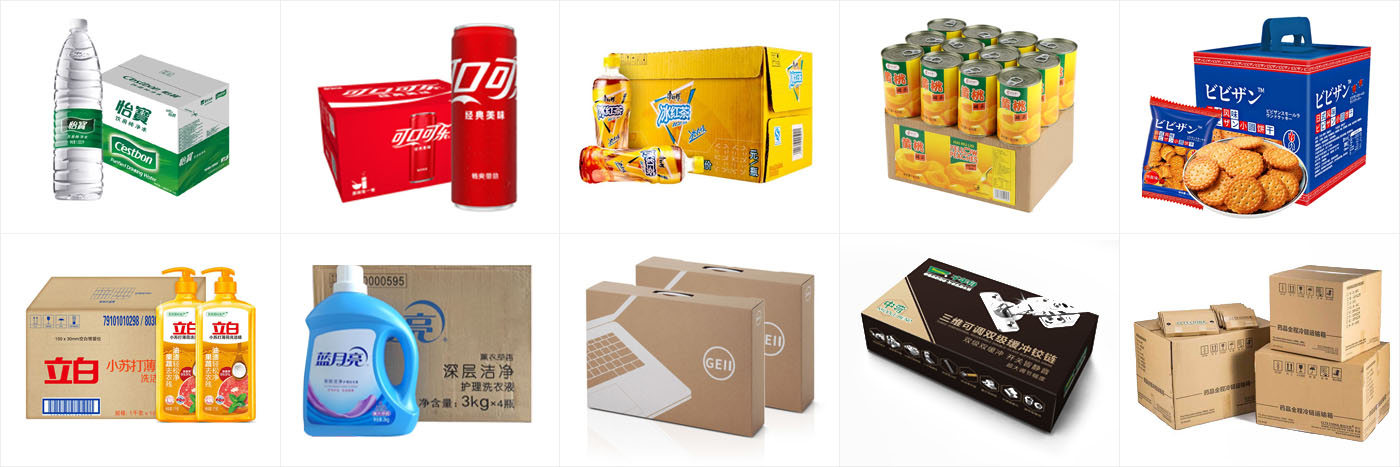

Product Application

Food and beverages (such as mineral water boxes, snack boxes), daily chemicals (such as laundry detergent boxes, cosmetic boxes), electronic products (such as mobile phone boxes, household appliances)