This is a system to stacking cases according to the pre-set program, using a robotic arm. It is a economic solution to make palletizing automatically, greatly save labor cost with reasonable investment.

Our Features:

1. Simple operation,flexible deployment,wide application.

2. Graphical progra mming, simple and efficient, you can easily use the robot without being proficient in progra mming languages. It takes half an hour to master the progra mming method, and one hour to complete simple progra mming.

3. Integrated design, lightweight and flexible, small footprint; workstation deployment of new tasks is simple, fast and efficient.

4. Widely used in food, medicine, 3C, daily chemicals, printing and other industries.

Consists:

Collaborative robot

Electrical box control cabinet

Column lifting shaft

Base + card board positioning

End effector

Operating system

Specifications:

Weight | 62kg |

Payload | 20kg |

Working radius | 1600 mm |

Maximum arms span | 1600 mm |

Rated voltage | Single phase 220v |

Maximum stack height | The maximum stacking height that can be lifted is 2100 mm (including pallets); generally up to 1600 mm (including pallets) |

Maximum pallet size | 1200 mm×1200 mm |

Stackable box dimensions | L(260-500)×W(200-450)×H(150-400) mm |

Maximum allowable load | 20kg |

Fastest stacking speed | Stacking up to 8 boxes per minute |

Working radius | Maximum working radius 1600 mm |

IP rating | The robot arm is IP54, the gripper and other accessories are IP32 compliant |

UI | Supports multiple safety inputs and outputs, including emergency stop, safety protection, administrator mode, and factory setting mode |

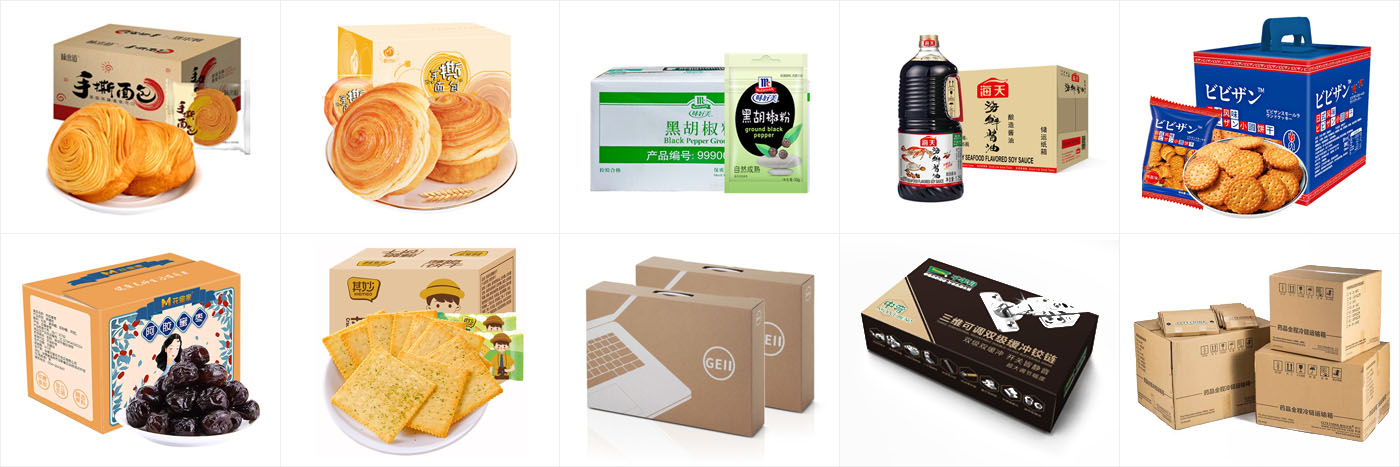

Product Application

Baking foods, snacks, seasonings, dairy products, lipsticks, skin care products, perfumes, medicine bottles, medicine plates, health care product boxes, mobile phones, circuit boards, and small car parts for stacking